Precision in Every Cut:

Lathe and Metalworking Solutions

Exploring the vital role of lathes in ensuring precision and efficiency across industries.

Get Started

About Vorxlog

We are dedicated to providing high-quality lathe products, as well as a range of metalworking solutions including Drilling, Turning, Slitting, Grooving, and Knurling. With years of experience in the industry, we have built a reputation for reliability and precision, and we are committed to meeting the unique needs of each of our clients.

Some Services We Offer

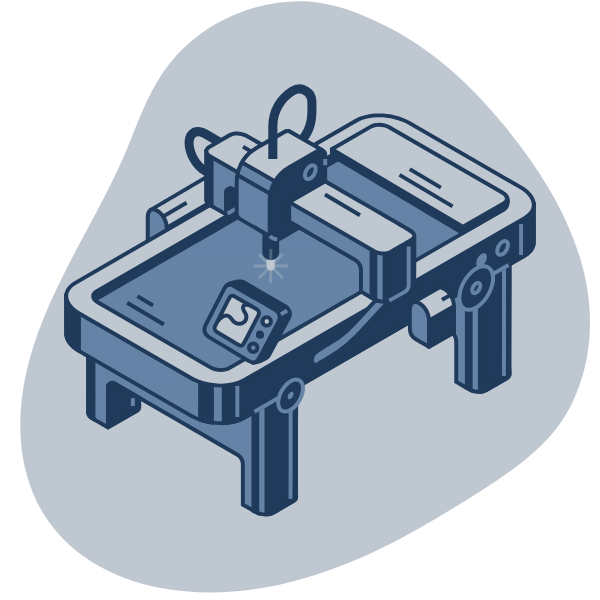

Drilling

Drilling services utilize advanced equipment and techniques to deliver accurate and high-quality results for our clients.

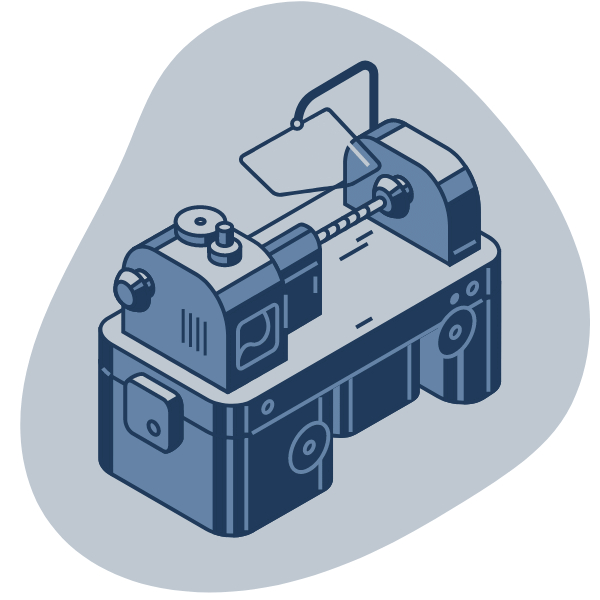

Turning

Turning services, we deliver precise and smooth finished products using state-of-the-art equipment and techniques..

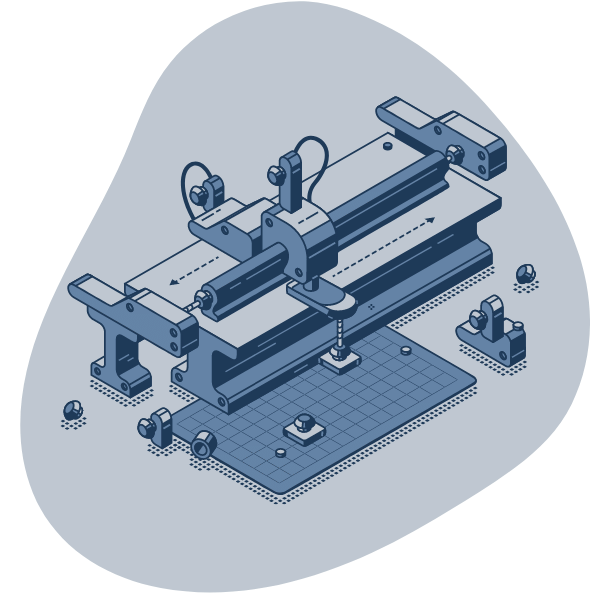

Slitting

Slitting services offer efficient and precise metal cutting solutions for a variety of industrial applications.

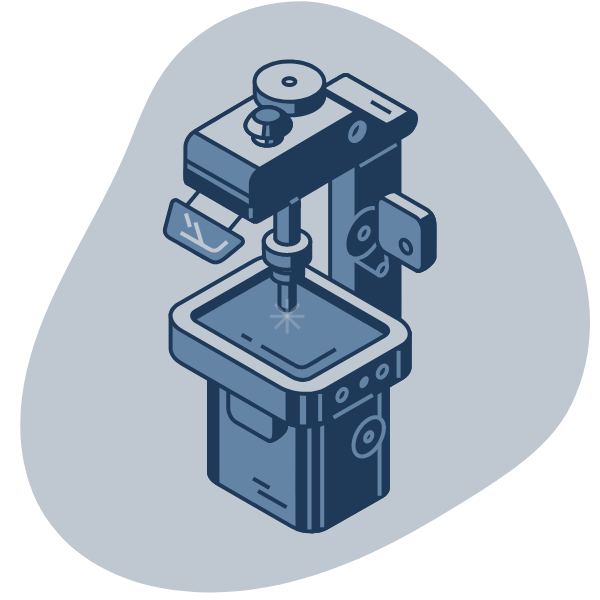

Grooving

Grooving services offer accurate and customizable solutions for creating grooves in metal parts.

Forging

Forging services offer precise shaping and customization of metal parts for various industrial applications.

Knurling

Knurling services offer precision and customization for creating patterns and textures on metal surfaces.

Why Choose Us

Rapid Samples

Our standard turnaround time for samples is 7-10 days.

Team Experience

Our experienced team sets itself apart from others in the industry.

Superior Quality

Inspection and quality control processes ensure a quality products.

On Time Delivery

Efficiently guarantee the timely arrival of the package.

We Believe In

Long Lasting Relationships.

Contact us today and our experts will promptly assist you with any information you need. We are committed to providing transparent and personalized solutions that meet your specific needs and budget. Get in touch with us to learn more and get started.

Your Questions Answered

Frequently Asked Questions

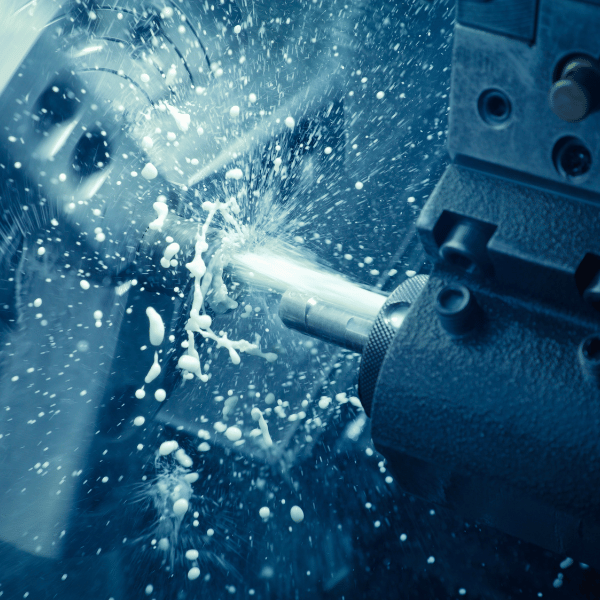

What is lathe machining?

Lathe machining is a type of machining process that involves the use of a lathe machine to remove material from a workpiece using cutting tools. The lathe machine holds the workpiece and rotates it against the cutting tool, which moves along the length of the workpiece to remove material and shape it into the desired form.

Lathe machining can be used to create a variety of shapes and features on a workpiece, including threads, holes, and grooves. It is commonly used in manufacturing processes to produce parts for a wide range of products, from simple components to complex machinery.

How does machining works?

Machining is a process used to remove material from a workpiece to create a desired shape or surface finish. The process typically involves using a cutting tool that is moved against the workpiece to remove material, creating chips that are removed from the cutting zone.

There are several types of machining processes, including turning, milling, drilling, and grinding. Each process involves using different tools and techniques to remove material in a specific way.

In turning, for example, a workpiece is rotated while a cutting tool is moved along the length of the workpiece to remove material and create a cylindrical shape. In milling, a cutting tool rotates and moves along multiple axes to remove material and create a variety of shapes and features.

The specific machining process used will depend on the material being machined, the desired shape and surface finish, and other factors such as the complexity of the part and the available machinery.

How much does machining cost?

The cost of machining can vary widely depending on a number of factors, including the type of machining process required, the complexity of the part, the size of the workpiece, the material being machined, and the quantity of parts being produced.

In general, the cost of machining includes the cost of the raw materials, the cost of the machining process itself (including labor, tooling, and equipment), and any additional costs such as finishing, assembly, and shipping.

How to reduce the cost of machined parts?

Reducing the cost of machined parts can be achieved through several strategies.

* Design for manufacturability

* Use the right materials

* Optimize machining parameters

* Use standard tooling and materials

* Minimize setup time

* Optimize batch sizes

Can I have samples before placing the order?

Sure, w offer prototyping or sample services to help customers evaluate and refine their designs before placing a full production order. Prototyping allows you to test the design and functionality of your parts before committing to a larger production run, helping to minimize the risk of costly errors or design flaws.

What are machining capabilities?

We mill and turn low quantities of parts very quickly. Typical quantities are one to 1000 pieces and manufacturing times are 3 business days. We offer product developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications.

Contact Us

We welcome you to contact us via message, phone call, or factory visit. Our team is always available to assist you and provide exceptional customer service.